About Us

Hi, my name is Polkovnikov Vlad.

I am the founder of PV-bags company. Let me tell you how we create your bags

5 steps to perfection

Working with leather is my passion

Step 1 – Designing the bag

Step 2 – Materials selection

Step 3 – Patterns

Step 4 – Hand sewing

Step 5 – Package

Every piece I create at my workshop is exclusively handmade involving the use of specific processing techniques and elaborate handwork. The extensive knowledge of the materials is key to the creation of high quality bags made to stand the test of time. The entire production is situated in one place what also helps to ensure no damaged or flawed product even by accident ever shipped to buyer. I believe the items I make are more than simple products but rather embodiment of my passion.

The first step is the idea. This means putting pen to paper and sketching out thoughts, usually over a cup of tea. Our design style is intentionally minimalist to achieve a fuss-free look that showcases the natural qualities of the vegetable tanned leather and beautifully handcrafted detailing

Choosing the right leather, hardware, accessories, threads are all of utmost importance.

More info about the raw materials used you may find here, each manufacturer whether it’s tannery, leather production or threads, is an entire separate world of its own history, tradition and expertise.

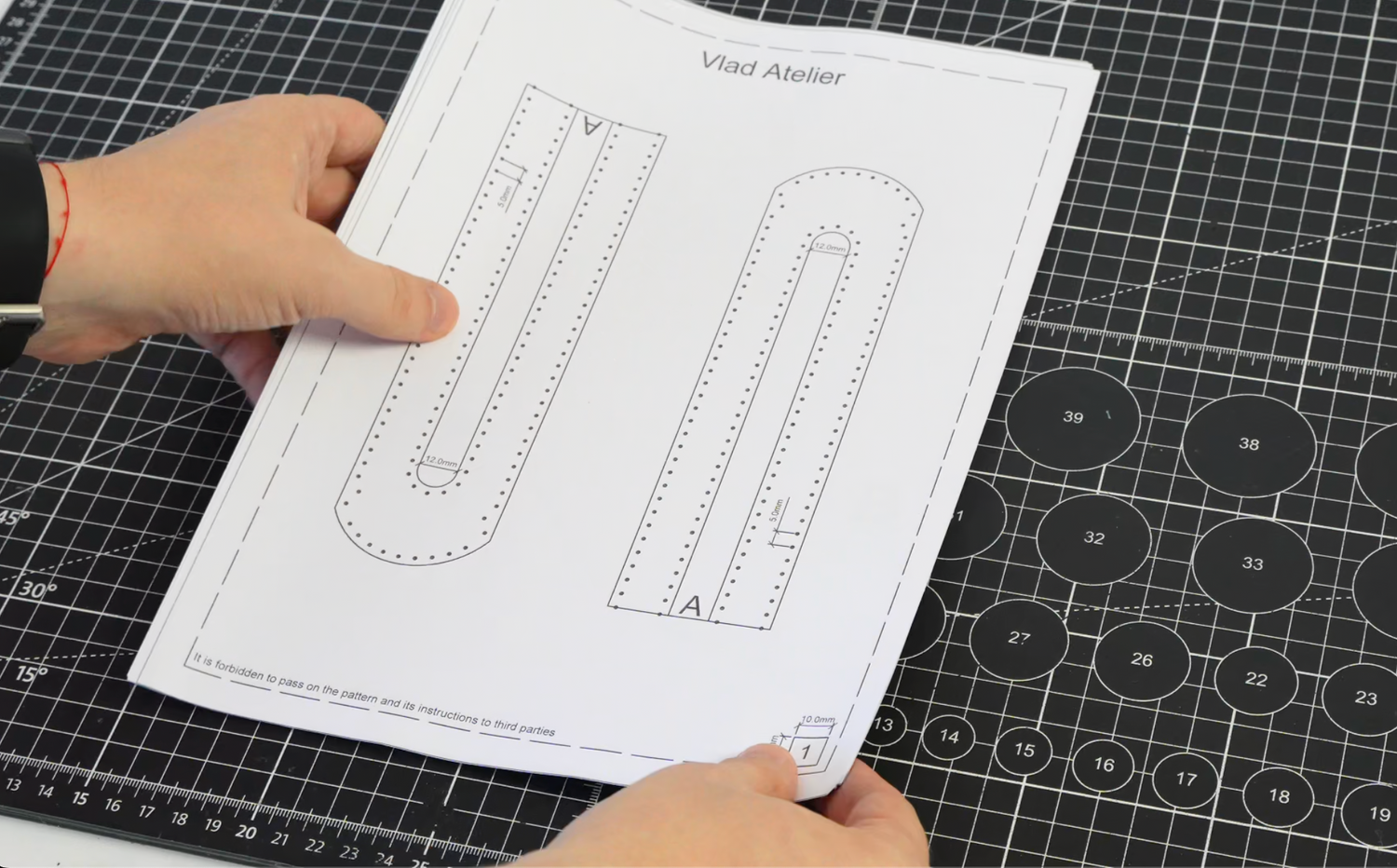

I personally design the bag patterns with the help of computer programs.

The integrity of the product, the evenness of the lines and the overall shape depend on how carefully the patterns are made.

The details of the product are processed and cut out by hand.

Before the advent of machines, everything that needed to be sewn was sewn by hand. And even now there are still craftsmen working in this way. Most of the items we produce are made in this way. In most cases, hand sewing on leather is used when higher quality leather goods are required. It was originally used in the manufacture of saddles.

For example, any thread damage in a machine stitch will first result in a few open stitches near the tear, and then soon the entire stitch will open up as well. With the saddle stitch technique, both stitches near the rip will remain intact, preventing further opening of the seam.